How it Works

The ITC is located at Basin Electric Power Cooperative’s Dry Fork Station, seven miles north of Gillette, Wyoming. Researchers at the ITC have access to scrubbed flue gas otherwise released from the plant, which is largely a combination of ambient air, water vapor and 12.5% carbon dioxide.

A steel duct connects the plants gas flue to the ITC. Technology positioned inside the plants’ exhaust flue allows researchers to divert flue gas to their testing facility when and as needed, where carbon dioxide molecules can be pulled and utilized.

Interested in testing? View our Interested Developers page for more information.

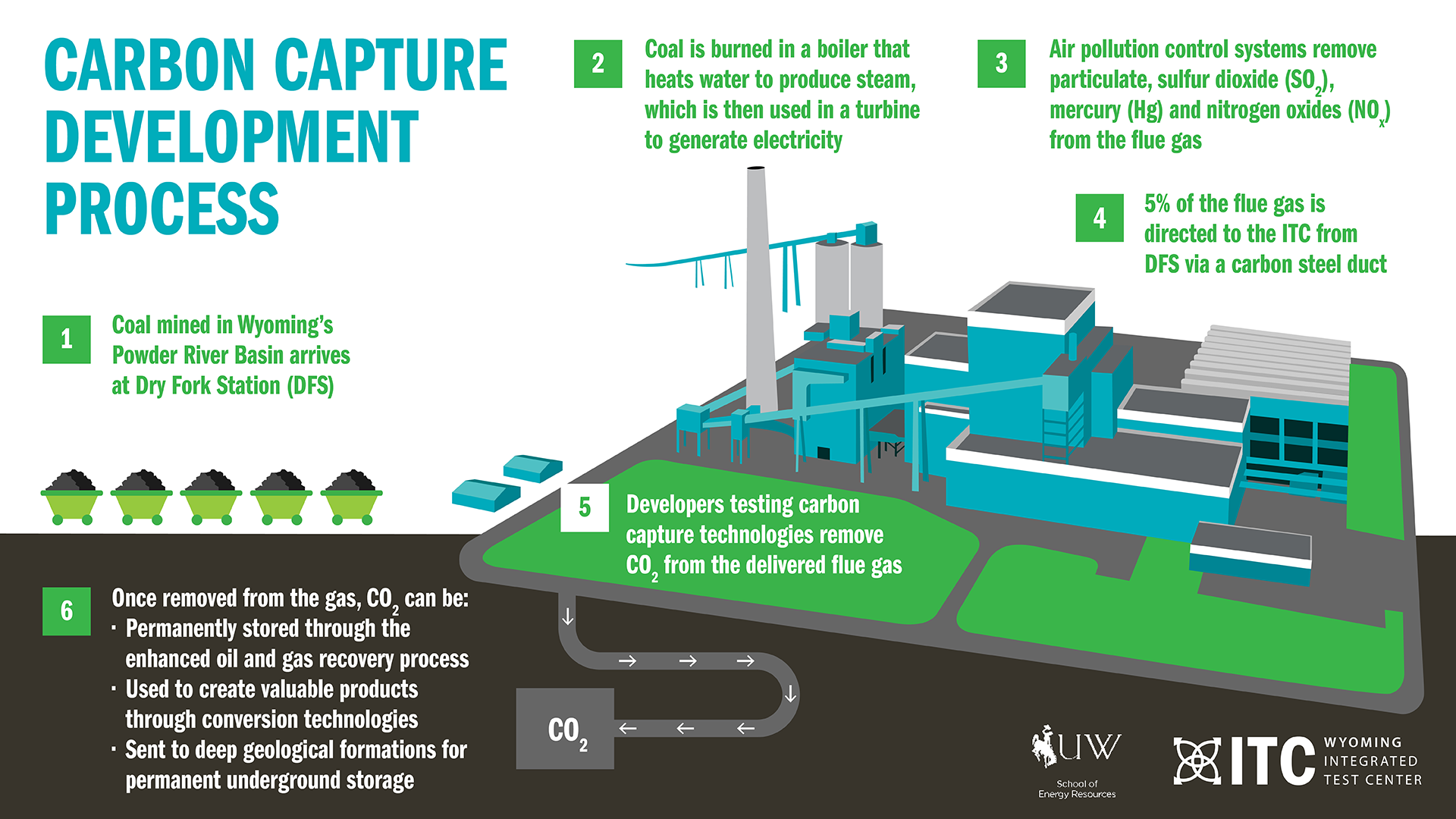

Carbon Capture Development Process

Mining

Wyoming provides about 40% of America’s coal through the surface mining in the Powder River Basin.

Transportation

Nearly all of the coal mined in the Powder River Basin is transported via train.

Production

At coal-fired power plants, water is turned into steam which drives generators to produce electricity. As coal burns, it first goes through a vacuum, which sometimes uses static electricity, to remove particles. It then goes through several “scrubbers” that remove sulfur dioxide (S2O) and nitrous oxide (NO2). After the scrubbers, carbon dioxide (CO2) and water vapor comes out of the gas flue.

Carbon Capture

The flue gas is delivered to the ITC via a carbon steel duct. A guillotine damper installed into the carbon steel tie-in duct gives researchers the ability to open and close the duct when they need flue gas. The damper pulls the flue gas after removal of S2O and NO2, opening it and closing it as needed for testing.

Research

The ITC has multiple demonstration sites. Each test center is provided with flue gas, power, and service water from the Dry Fork Station. The test centers have access to varying levels of power based on their specific project needs.